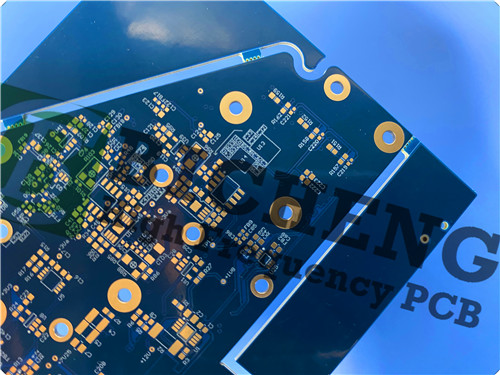

FR408HR High-Performance 4-Layer PCB Specifications for Enhanced Reliability

1.Essential Specifications for FR408HR PCB

| Specification | Details |

|---|---|

| Board Type | 4 Layers |

| Material Type | High-performance FR408HR |

| Solder Mask | Dual-sided, Blue |

| Silkscreen Print | Both sides in white |

| Surface Finish | ENIG |

| Total Board Thickness | 1.6mm +/- 10% |

| Dimensions | 140mm x 160mm (1 Piece) |

| Minimum Hole Size | 0.3mm |

| Solder Mask Thickness | 10µm |

| Minimum Dielectric Thickness | 100µm |

| Minimum Trace Width | 102µm |

| Minimum Spacing | 102µm |

| Blind Via | No |

| Buried Via | No |

| Filled and Capped Via | Yes |

2.PCB Stack-up Structure: 4-layer Rigid PCB (Component Side on Top)

| MATERIAL | COPPER LAYER | THICKNESS (µm) | SPECIFICATION |

|---|---|---|---|

| COPPER | 1 | 45 | 35µm base copper + 17µm plating |

| FR408HR | Prereg | 100 | IPC-4101/24 |

| COPPER | 2 | 35 | |

| FR408HR | Core | 1230 | IPC-4101/24 |

| COPPER | 3 | 35 | |

| FR408HR | Prepreg | 100 | IPC-4101/24 |

| COPPER | 4 | 45 | 35µm base copper + 17µm plating |

3.PCB Statistics:

Total Components: 92

Total Pads: 201

Through Hole Pads: 75

Top SMT Pads: 87

Bottom SMT Pads: 39

Vias: 72

Nets: 8

4.Additional Details

| Specification | Details |

|---|---|

| Copper Layer 1 | 35 µm |

| F4BTMS1000 Core | 6.35 mm (250 mil) |

| Copper Layer 2 | 35 µm |

| Prepreg RO4450F | 0.102 mm (4 mil) |

| Copper Layer 3 | 35 µm |

| F4BTMS1000 Core | 6.35 mm (250 mil) |

| Copper Layer 4 | 35 µm |

5.Overview of FR408HR Laminates

The FR408HR laminate and prepreg materials are produced using Isola's cutting-edge multifaceted resin system, enhanced with electrical grade (E-glass) fabric. This innovative approach yields a 30% increase in Z-axis expansion and provides 25% greater electrical bandwidth (lower losses) compared to competing products in the market. These features, combined with exceptional moisture resistance at reflow, ensure a product that excels thermally and electrically.

Moreover, the FR408HR system exhibits laser fluorescence and UV blocking capabilities, maximizing compatibility with Automated Optical Inspection (AOI) systems, optical positioning systems, and photo-imagable solder mask imaging solutions.

6.Key Features of FR408HR:

Glass Transition Temperature (Tg): 190°C by DSC

Dielectric Constant: 3.65 @ 10GHz

Dissipation Factor: 0.0095 @ 10GHz

RoHS Compliant: Yes

Compatible with FR-4 Processes: Yes

CAF Resistant: Yes

Lead-Free Assembly Compatibility: Yes

Pitch Capability: 0.8 mm

Reflow Capability: 6x 260°C

Solder Float Capability: 6x 288°C

Delamination Resistance (TMA): T260 > 60 minutes, T288 > 30 minutes

Flammability Rating for Laminate & Laminated Prepreg: UL-94 V0

7.Typical Applications of FR408HR PCBs:

High-Density Interconnect (HDI) PCBs

High-Speed Digital Circuits

Applications Requiring High Thermal Reliability

Networking and Communication Devices

Storage Solutions and Peripherals

Medical, Industrial, and Instrumentation Equipment